Build your business with Chemcut, the global leader in wet processing equipment

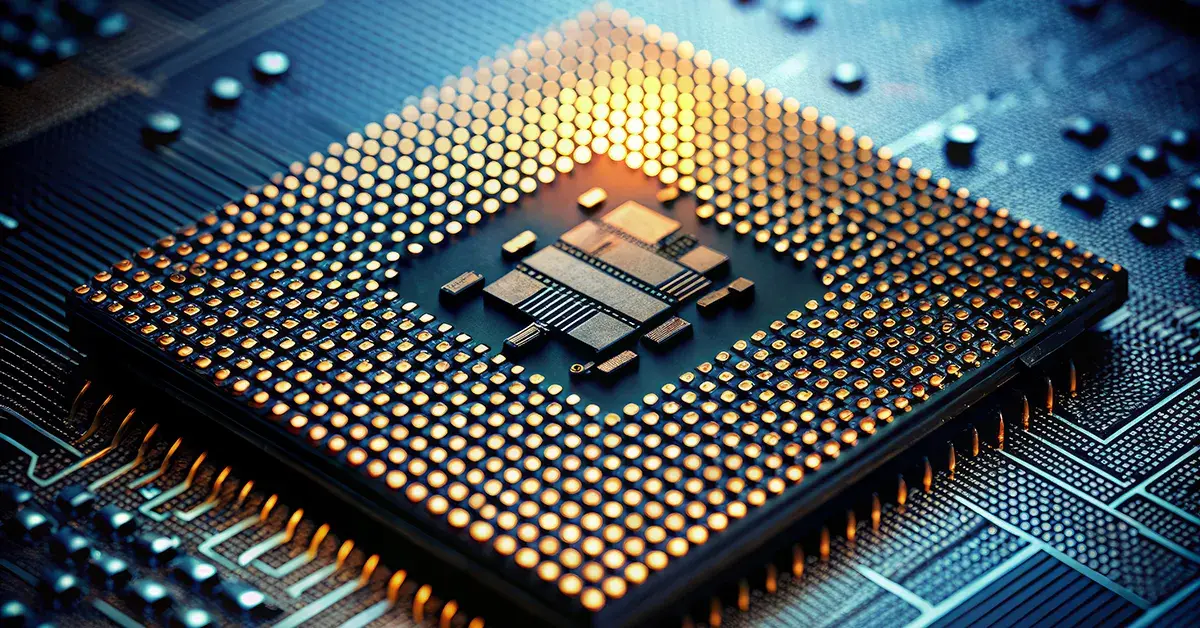

Whether you are engaged in photo chemical milling, chemical engraving, PCB manufacturing, metal finishing, or other wet processing application, our expert design, manufacturing efficiency, rigorous quality control, and long-term support make Chemcut your ideal partner.

Let's TalkBOUNDLESS INNOVATION. UNBEATABLE PRECISION.

Chemcut is the world’s leading developer of wet processing equipment for photo chemical milling of thin metal parts, chemical engraving of signs and nameplates, etching printed circuit boards, and metal finishing. Why would you settle for anything less than the best?

VIEW OUR PRODUCTSCustom Manufactured Parts by Chemcut

A new Division. The Same Chemcut Reliability.

VIEW OUR CAPABILITIESChemcut Manufactures Wet Processing Equipment for Industry Leaders in…

Customize your own equipment. Tell us what you need, and we will engineer a machine and process around your product.

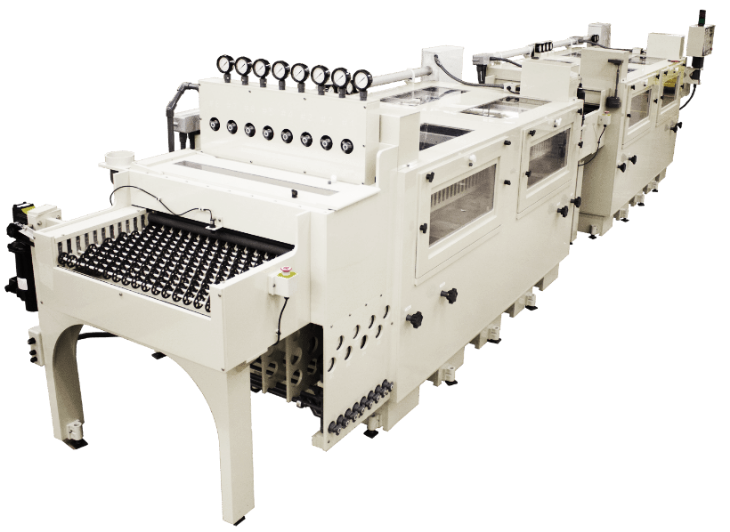

Take A Look At Some Of Our Expertly Crafted Wet Processing Equipment For Etching, Developing, Stripping, Plating, and more.

Check Our Latest Posts

Optimize a Wet Processing for Design & Spacing

Effective space planning and design are critical to the success of wet processing facilities....

How to Scale Up Manufacturing | Strategies to Improve Efficiency & Reduce Costs

Scaling up manufacturing presents both challenges and opportunities for engineers who must...

How to Scale Up Production with Chemical Milling & Etching

Chemical milling and etching are powerful techniques widely used in industries requiring precise,...

High quality products are made with high quality equipment. Stake your reputation on Chemcut.

Already a customer?

Chemcut’s commitment to you goes beyond the sale. We keep your equipment running with the industry’s best post-sales support, which includes our in-house R&D lab and global field service assistance.

We also maintain the industry’s largest and most diverse inventory of high-quality replacement parts to ensure prompt delivery regardless of the type or age of your Chemcut or MEI Division equipment.