Metal Finishing, Chemical Cleaning, and Non-Metal Treatments

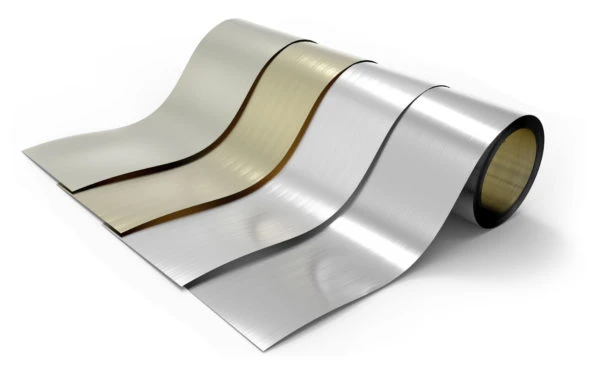

What is Metal Finishing?

Metal Finishing is the process of changing the surface of a metal to improve its appearance, functionality, or cleanliness.

Metal finishing to improve the functionality includes increasing electrical conductivity, corrosion resistance, surface roughness so photoresist adheres to the surface better, and much more.

Metal appearance improvements include polishing, removing smut, or micro etching the surface for a matte finish.

Metal surface cleaning is very popular and is commonly used to remove oils, organics, oxidation, and other small particles that are stuck to the metal surface.

Metal finishing can be accomplished chemically or mechanically, and Chemcut offers both surface treatments.

Plating is another form of metal finishing. Plating is an additive process where metal is deposited on top of a surface electrolytically or, in Chemcut’s case, electroless.

Chemical Cleaning

Ultrasonic Cleaning

Electroless Plating

Mechanical Cleaning

Micro Etching

Passivation

Acid Cleaner. The goal is to remove any contaminants that may be on the surface. This metal acid clean will micro etch the surface (depending on the metal) which increases lamination adhesion.

Alkaline Cleaner. The goal of this step is to remove all oils and organics from the surface.

Anti-Tarnish. Aids in corrosion resistance.

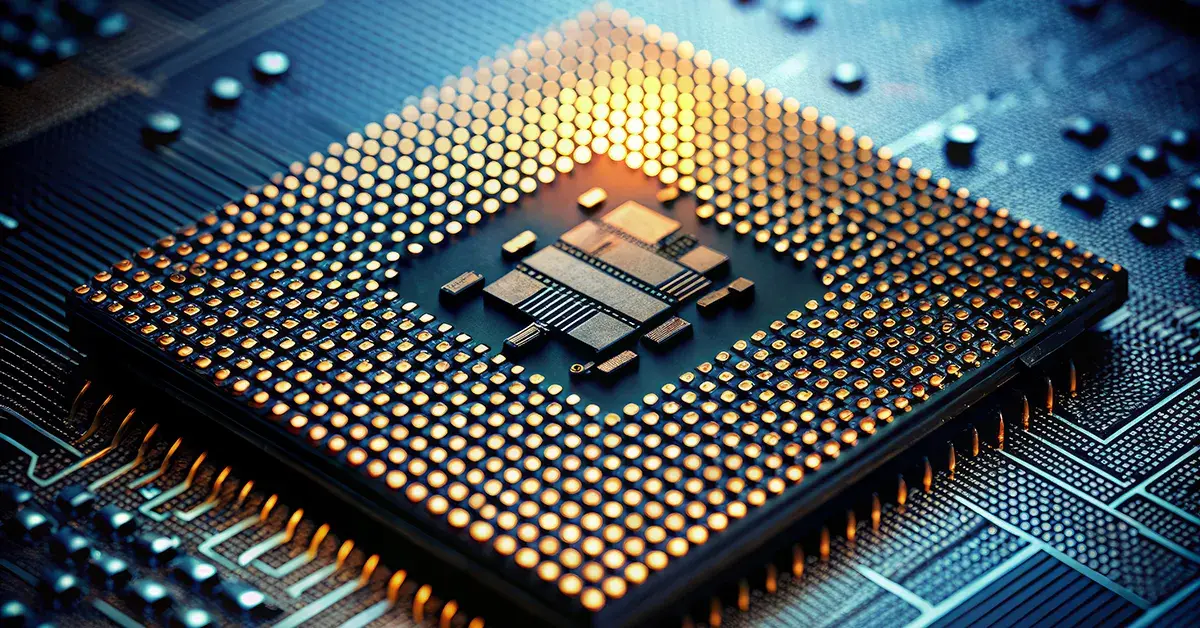

Inner-layer bonding treatments for PCB multilayer construction. Chemcut offers equipment for all of the propriety chemistries that are used as a surface treatment that adds an oxide layer to the surface to aid with lamination adhesion.

Through-hole metallization process for PCB fabrication

Copper Conveyorized Plating is an additive process where you are plating copper on a surface. Our plating lines are electroless. This means copper is plated through a chemical reaction instead of using an electrical current. This process is very common in PCB manufacturing to create or increase electrical conductivity.

Electrolytic Cleaning – completed before the micro etch process to remove the chromate layer on PCB / copper foil. The chromate layer will protect the surface from micro etching and needs to be removed by electrolytic cleaning PCB copper.

Glass Cleaning. To remove oils, dust, and handling marks from the glass surface. Clean, rinse, and dry. The systems can be designed for high-temperature cleaning as high as 180 F.

Immersion Silver

Immersion Tin

Outer-layer bonding treatments for soldermask coatings prior to Ni/Au plating or Sn plating.

Mechanical Deburr: Typically used on rigid metals and PCBs after drilling to deburr the holes. Deburr is more aggressive than the scrubber and will result in a uniform, parallel grain-finished surface.

Mechanical Scrubber is used on flexible and rigid metals as a metal and/or PCB cleaner. The scrubber is less aggressive than the deburr and will result in a uniform, parallel grain-finished surface like the deburr.

Micro Etching is used for several reasons. The most common we see are for increasing lamination adhesion, creating a matte finish, and thinning of metal. A micro etch can be completed on nearly any metal like chemical etching. Below is a list of common micro etching lines.

- Stainless Steel Micro Etcher

- Copper Micro Etcher

- Titanium Micro Etcher

- Glass Frosting

- Specialty Metal Micro Etcher

XLi Chemical Cleaning System

- 20″

- 30″

- 40″

- 50″

- 60″

- Cleaner (Stand Alone)

- Alkaline Clean to Acid Clean

- Custom Size (1 to as many chambers as you want)

- Acid Cleaner

- Alkaline Cleaner

219 Scrubber

- Single-sided abrasive brush

- Tough reinforced conveyor belt supports small parts

121 Brush Cleaner

- Wet Brushing

- Oscillating Brushes

- Choice of bristle or compressed brushes

- Brushing

- Cleaner

- Finishing

- Remove Polishing

2300 Series Dryer

- 15″

- 20″

- 30″

- 40″

- Stand-alone drying system

- Portable unit (move anywhere in the shop) or fix it in place

604 Deburrer

- 2 oscillating brushes

- Built-in Rinse and Dryer

- Post PCB drilling

- Post punching operations

Ion Exchange System

- Closed-loop system

- Decrease your water usage by connecting an ion exchange to your rinse water

Related Resources

Optimize a Wet Processing for Design & Spacing

Effective space planning and design are critical to the success of wet processing facilities....

How to Scale Up Manufacturing | Strategies to Improve Efficiency & Reduce Costs

Scaling up manufacturing presents both challenges and opportunities for engineers who must...

How to Scale Up Production with Chemical Milling & Etching

Chemical milling and etching are powerful techniques widely used in industries requiring precise,...

High quality products are made with high quality equipment. Stake your reputation on Chemcut.

Already a customer?

Chemcut’s commitment to you goes beyond the sale. We keep your equipment running with the industry’s best post-sales support, which includes our in-house R&D lab and global field service assistance.

We also maintain the industry’s largest and most diverse inventory of high-quality replacement parts to ensure prompt delivery regardless of the type or age of your Chemcut or MEI Division equipment.