Printed Circuit Board (PCB) Fabrication Using Chemical Etching

Products & Processes Run on Chemcut PCB Etching Machines

- 2 mil core inner layers

- Flexible reel-to-reel Kapton

- 250 mil multi-layers

- Rigid FR4

Fine Line PCB Etching

2 mil line and space at production volumes

Thin Material Transport for PCB

-

2 mil material can be transported with ease

Etch & Capabilities Testing

Develop – Etch – Strip Line

Strip – Etch – Strip Line

Cupric Chloride Etch Line

Developing Systems

Stripping Systems

Mechanical Scrubbing and Deburr

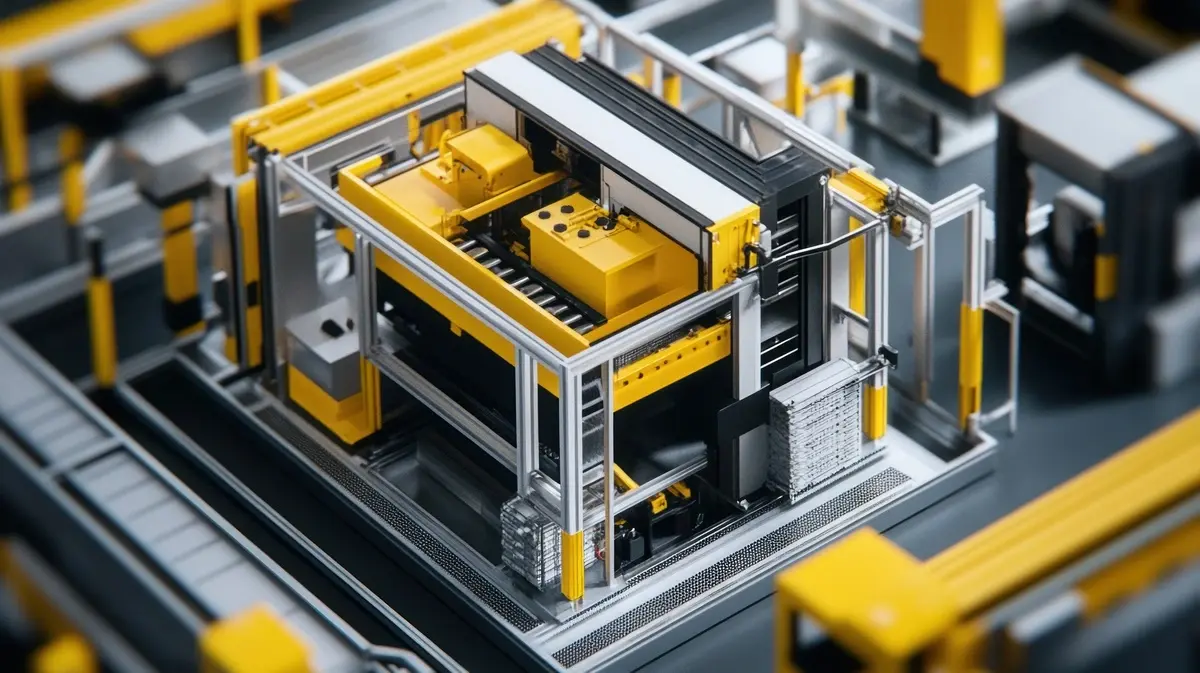

Chemcut PCB Etching Machines for Fabrication of PCB

- Do you prefer to control the spray pressure of every spray tube or zone (depends on setup) instead of the options above?

Then check out our XLi High-Resolution etcher. This module allows you to control the spray pressure of every spray tube or zone from your PLC.

We have designed our the XLi High-Resolution etcher to have five zones—top and bottom—where you can control the pressure of each spray tube or zone. The etcher will allow you to even the etch side to side for PCB fabrication and will allow you to etch one side more than the other without getting in the etch chamber to make adjustments. - One of the most popular money-saving options is our Regeneration system. For cupric chloride, Chemcut’s regeneration system makes the chemistry last indefinitely! The regeneration system will automatically add hydrochloric acid and sodium chlorate as you etch more copper. We also offers a chlorine gas regeneration system for cupric chloride etching.

Other Popular Options for the PCB Etching Process:

2300 Series Chemical Cleaning System

- 15″

- 20″

- 30″

- Cleaner (Stand Alone)

- Alkaline Clean to Acid Clean

- Custom Size (1 to as many chambers as you want)

- Acid Cleaner

- Alkaline Cleaner

2300 Series Developing System

- 15″

- 20″

- 30″

- Custom Size (1 to as many chambers as you want)

- Developer (Stand Alone)

- DES (Develop – Etch – Strip)

- 1% Potassium Carbonate

- 1% Sodium Carbonate

- dry film photoresists

- liquid photoresists

- Aqueous solder mask resist (dry and liquid)

- And many more resists

2300 Series Dryer

- 15″

- 20″

- 30″

- 40″

- Stand-alone drying system

- Portable unit (move anywhere in the shop) or fix it in place

2300 Series Etching System

- 15″

- 20″

- 30″

- Custom Size (1 to as many chambers as you want)

- DES (Develop – Etch – Strip)

- Etcher (Stand Alone)

- SES (Strip – Etch – Strip)

- Alkaline Etchant

- Cupric Chloride Etchant

- Ferric chloride Etchant

- Hydrofluoric Acid (HF)

- Micro etch

- Aluminum

- Copper

- Glass

- Steel

- Titanium

- And more

2300 Series Stripping System

- 15″

- 20″

- 30″

- Custom Size (1 to as many chambers as you want)

- DES (Develop – Etch – Strip)

- SES (Strip – Etch – Strip)

- Stripper (Stand Alone)

- Metal Resist Stripper

- Proprietary Aqueous or Semi-Aqueous Stripper

- Potassium Hydroxide

- Sodium Hydroxide

XLi Chemical Cleaning System

- 20″

- 30″

- 40″

- 50″

- 60″

- Cleaner (Stand Alone)

- Alkaline Clean to Acid Clean

- Custom Size (1 to as many chambers as you want)

- Acid Cleaner

- Alkaline Cleaner

XLi Developing Systems

- 20″

- 30″

- 40″

- 50″

- 60″

- Custom Size (1 to as many chambers as you want)

- Developer (Stand Alone)

- DES (Develop – Etch – Strip)

- 1% Potassium Carbonate

- 1% Sodium Carbonate

XLi Etching Systems

- 20″

- 30″

- 40″

- 50″

- 60″

- Custom Size (1 to as many chambers as you want)

- DES (Develop – Etch – Strip)

- Etcher (Stand Alone)

- SES (Strip – Etch – Strip)

- Alkaline Etchant

- Cupric Chloride Etchant

- Ferric chloride Etchant

- Hydrofluoric Acid (HF)

- Micro etch

- Aluminum

- Copper

- Glass

- Steel

- Titanium

- And more

XLi Stripping Systems

- 20″

- 30″

- 40″

- 50″

- 60″

- Custom Size (1 to as many chambers as you want)

- DES (Develop – Etch – Strip)

- SES (Strip – Etch – Strip)

- Stripper (Stand Alone)

- Metal Resist Stripper

- Proprietary Aqueous or Semi-Aqueous Stripper

- Potassium Hydroxide

- Sodium Hydroxide

XLi with External Automatic Pressure Adjust

Control the spray pressure of each spray tube using the PLC instead of the throttling screw.

- 20″

- 30″

- 40″

- 50″

- 60″

- Custom Size (1 to as many chambers as you want)

- DES (Develop – Etch – Strip)

- Etcher (Stand Alone)

- SES (Strip – Etch – Strip)

- Alkaline Etchant

- Cupric Chloride Etchant

- Ferric chloride Etchant

- Hydrofluoric Acid (HF)

- Micro etch

- Aluminum

- Copper

- Glass

- Steel

- Titanium

- And more

604 Deburrer

- 2 oscillating brushes

- Built-in Rinse and Dryer

- Post PCB drilling

- Post punching operations

219 Scrubber

- Single-sided abrasive brush

- Tough reinforced conveyor belt supports small parts

936 Web Filtering System

Removes these from rinse water: Metal fines, Brush particles, Oils and other contaminates.

121 Brush Cleaner

- Wet Brushing

- Oscillating Brushes

- Choice of bristle or compressed brushes

- Brushing

- Cleaner

- Finishing

- Remove Polishing

990D Electroless Plating System

Product Lines for Electrolytic and Electroless Plating: CC8000, Dip Tanks, XLi, 2300 Series

- Desmear

- Electroless Copper Plating

- Electroless Nickel Plating

- Electrolytic Copper Plating

- Electrolytic Gold Plating

- Electrolytic Silver Plating

- Electrolytic Tin Plating

- Immersion Gold Plating

- Immersion Silver Plating

- Immersion Tin Plating

- Ni/Au Plating

- PTH (Plated through-hole) Any discussion on this topic should include your chemistry supplier as well. It is critical that the bath for PTH is monitored closely.

- Inner layer bonding operations: brown oxide (Bondfilm, Multibond, etc.), (white ‘oxide’ – immersion Tin)

Etch Adjust Module (EAM)

- CC8000 Etching Systems

- XLi Etching Systems

- Plated boards: Correct side to side etch difference when one side is plated more

- Fine-tune very small features

Ion Exchange System

- Closed-loop system

- Decrease your water usage by connecting an ion exchange to your rinse water

CC8000 Chemical Cleaning System

- 20″

- 30″

- 40″

- 50″

- 60″

- Cleaner (Stand Alone)

- Alkaline Clean to Acid Clean

- Custom Size (1 to as many chambers as you want)

- Acid Cleaner

- Alkaline Cleaner

CC8000 Developing Systems

- 20″

- 30″

- 40″

- 50″

- 60″

- Custom Size (1 to as many chambers as you want)

- Developer (Stand Alone)

- DES (Develop – Etch – Strip)

- 1% Potassium Carbonate

- 1% Sodium Carbonate

- dry film photoresists

- liquid photoresists

- Aqueous solder mask resist (dry and liquid)

- And many more resists

CC8000 Etching Systems

- 20″

- 30″

- 40″

- 50″

- 60″

- Custom Size (1 to as many chambers as you want)

- DES (Develop – Etch – Strip)

- Etcher (Stand Alone)

- SES (Strip – Etch – Strip)

- Alkaline Etchant

- Cupric Chloride Etchant

- Ferric chloride Etchant

- Hydrofluoric Acid (HF)

- Micro etch

- Aluminum

- Copper

- Glass

- Steel

- Titanium

- And more

CC8000 Stripping Systems

- 20″

- 30″

- 40″

- 50″

- 60″

- Custom Size (1 to as many chambers as you want)

- DES (Develop – Etch – Strip)

- SES (Strip – Etch – Strip)

- Stripper (Stand Alone)

- Sodium Hydroxide

- Potassium Hydroxide

- Proprietary Aqueous or Semi-Aqueous Stripper

- Metal Resist Stripper

Related Resources

Optimize a Wet Processing for Design & Spacing

Effective space planning and design are critical to the success of wet processing facilities....

How to Scale Up Manufacturing | Strategies to Improve Efficiency & Reduce Costs

Scaling up manufacturing presents both challenges and opportunities for engineers who must...

How to Scale Up Production with Chemical Milling & Etching

Chemical milling and etching are powerful techniques widely used in industries requiring precise,...

High quality products are made with high quality equipment. Stake your reputation on Chemcut.

Already a customer?

Chemcut’s commitment to you goes beyond the sale. We keep your equipment running with the industry’s best post-sales support, which includes our in-house R&D lab and global field service assistance.

We also maintain the industry’s largest and most diverse inventory of high-quality replacement parts to ensure prompt delivery regardless of the type or age of your Chemcut or MEI Division equipment.