Photo Etching & Chemical Milling Equipment

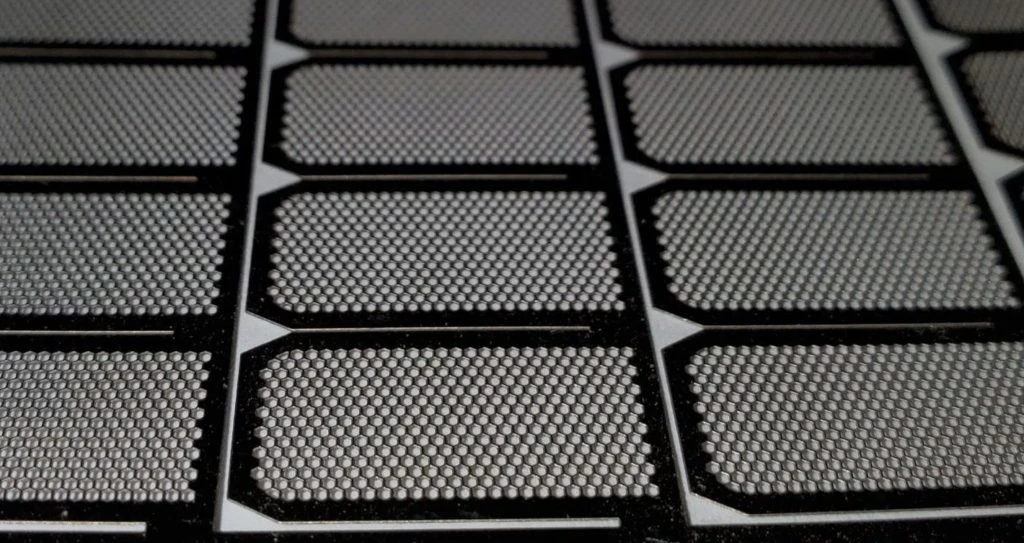

What is Photo Etching?

Photo etching is the process of removing metal by chemical etching and is ideally suited to produce flat, relatively thin parts of unlimited configurations.

Photo etching is also known as metal etching, chemical milling, acid etching, and stainless-steel etching.

If you want to learn more about the benefits of chemical etching and why you should consider it, please see our page on etching.

Popular Chemical Etching Lines for Photo Metal Etching

Explore our range of Chemical Etching lines, each designed and built to accommodate your specific process. When you are ready, contact our expert team to design the solution you need.

Popular Chemical Etching Lines for Photo Metal Etching

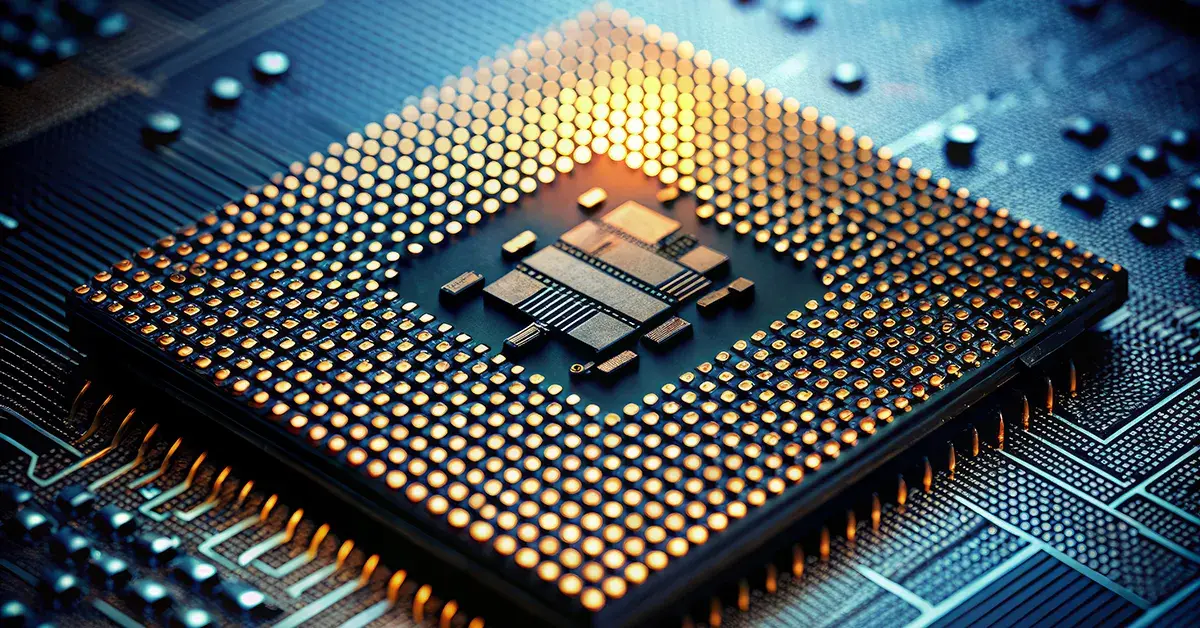

- Copper Etcher

- PCB Etcher

- Copper Etcher

- Stainless Steel Etcher

- PCB Etcher

- Specialty Metal Etcher

- Titanium Etching

- Specialty Metal Etcher

Popular Equipment Options for the Photo Etch Process

Specific gravity and drip pans are highly recommended options to go along with Chemcut’s photo etch processing equipment. Additional options to improve your process can be found on our Products page.

XLi with External Automatic Pressure Adjust

Control the spray pressure of each spray tube using the PLC instead of the throttling screw.

- 20″

- 30″

- 40″

- 50″

- 60″

- Custom Size (1 to as many chambers as you want)

- DES (Develop – Etch – Strip)

- Etcher (Stand Alone)

- SES (Strip – Etch – Strip)

- Alkaline Etchant

- Cupric Chloride Etchant

- Ferric chloride Etchant

- Hydrofluoric Acid (HF)

- Micro etch

- Aluminum

- Copper

- Glass

- Steel

- Titanium

- And more

XLi Chemical Cleaning System

- 20″

- 30″

- 40″

- 50″

- 60″

- Cleaner (Stand Alone)

- Alkaline Clean to Acid Clean

- Custom Size (1 to as many chambers as you want)

- Acid Cleaner

- Alkaline Cleaner

XLi Developing Systems

- 20″

- 30″

- 40″

- 50″

- 60″

- Custom Size (1 to as many chambers as you want)

- Developer (Stand Alone)

- DES (Develop – Etch – Strip)

- 1% Potassium Carbonate

- 1% Sodium Carbonate

XLi Etching Systems

- 20″

- 30″

- 40″

- 50″

- 60″

- Custom Size (1 to as many chambers as you want)

- DES (Develop – Etch – Strip)

- Etcher (Stand Alone)

- SES (Strip – Etch – Strip)

- Alkaline Etchant

- Cupric Chloride Etchant

- Ferric chloride Etchant

- Hydrofluoric Acid (HF)

- Micro etch

- Aluminum

- Copper

- Glass

- Steel

- Titanium

- And more

XLi Stripping Systems

- 20″

- 30″

- 40″

- 50″

- 60″

- Custom Size (1 to as many chambers as you want)

- DES (Develop – Etch – Strip)

- SES (Strip – Etch – Strip)

- Stripper (Stand Alone)

- Metal Resist Stripper

- Proprietary Aqueous or Semi-Aqueous Stripper

- Potassium Hydroxide

- Sodium Hydroxide

121 Brush Cleaner

- Wet Brushing

- Oscillating Brushes

- Choice of bristle or compressed brushes

- Brushing

- Cleaner

- Finishing

- Remove Polishing

219 Scrubber

- Single-sided abrasive brush

- Tough reinforced conveyor belt supports small parts

2300 Series Chemical Cleaning System

- 15″

- 20″

- 30″

- Cleaner (Stand Alone)

- Alkaline Clean to Acid Clean

- Custom Size (1 to as many chambers as you want)

- Acid Cleaner

- Alkaline Cleaner

2300 Series Developing System

- 15″

- 20″

- 30″

- Custom Size (1 to as many chambers as you want)

- Developer (Stand Alone)

- DES (Develop – Etch – Strip)

- 1% Potassium Carbonate

- 1% Sodium Carbonate

- dry film photoresists

- liquid photoresists

- Aqueous solder mask resist (dry and liquid)

- And many more resists

2300 Series Dryer

- 15″

- 20″

- 30″

- 40″

- Stand-alone drying system

- Portable unit (move anywhere in the shop) or fix it in place

2300 Series Etching System

- 15″

- 20″

- 30″

- Custom Size (1 to as many chambers as you want)

- DES (Develop – Etch – Strip)

- Etcher (Stand Alone)

- SES (Strip – Etch – Strip)

- Alkaline Etchant

- Cupric Chloride Etchant

- Ferric chloride Etchant

- Hydrofluoric Acid (HF)

- Micro etch

- Aluminum

- Copper

- Glass

- Steel

- Titanium

- And more

2300 Series Stripping System

- 15″

- 20″

- 30″

- Custom Size (1 to as many chambers as you want)

- DES (Develop – Etch – Strip)

- SES (Strip – Etch – Strip)

- Stripper (Stand Alone)

- Metal Resist Stripper

- Proprietary Aqueous or Semi-Aqueous Stripper

- Potassium Hydroxide

- Sodium Hydroxide

2800 Drawer Etcher

- An adjustable drawer type rack

- Loads parts horizontally up to size 21″ x 21″

- Oscillating spray tubes

- Oscillating rack to maximize etchant movement

604 Deburrer

- 2 oscillating brushes

- Built-in Rinse and Dryer

- Post PCB drilling

- Post punching operations

CC8000 Chemical Cleaning System

- 20″

- 30″

- 40″

- 50″

- 60″

- Cleaner (Stand Alone)

- Alkaline Clean to Acid Clean

- Custom Size (1 to as many chambers as you want)

- Acid Cleaner

- Alkaline Cleaner

CC8000 Developing Systems

- 20″

- 30″

- 40″

- 50″

- 60″

- Custom Size (1 to as many chambers as you want)

- Developer (Stand Alone)

- DES (Develop – Etch – Strip)

- 1% Potassium Carbonate

- 1% Sodium Carbonate

- dry film photoresists

- liquid photoresists

- Aqueous solder mask resist (dry and liquid)

- And many more resists

CC8000 Etching Systems

- 20″

- 30″

- 40″

- 50″

- 60″

- Custom Size (1 to as many chambers as you want)

- DES (Develop – Etch – Strip)

- Etcher (Stand Alone)

- SES (Strip – Etch – Strip)

- Alkaline Etchant

- Cupric Chloride Etchant

- Ferric chloride Etchant

- Hydrofluoric Acid (HF)

- Micro etch

- Aluminum

- Copper

- Glass

- Steel

- Titanium

- And more

CC8000 Stripping Systems

- 20″

- 30″

- 40″

- 50″

- 60″

- Custom Size (1 to as many chambers as you want)

- DES (Develop – Etch – Strip)

- SES (Strip – Etch – Strip)

- Stripper (Stand Alone)

- Sodium Hydroxide

- Potassium Hydroxide

- Proprietary Aqueous or Semi-Aqueous Stripper

- Metal Resist Stripper

Etch Adjust Module (EAM)

- CC8000 Etching Systems

- XLi Etching Systems

- Plated boards: Correct side to side etch difference when one side is plated more

- Fine-tune very small features

936 Web Filtering System

Removes these from rinse water: Metal fines, Brush particles, Oils and other contaminates.

Ion Exchange System

- Closed-loop system

- Decrease your water usage by connecting an ion exchange to your rinse water

Related Resources

Optimize a Wet Processing for Design & Spacing

Effective space planning and design are critical to the success of wet processing facilities....

How to Scale Up Manufacturing | Strategies to Improve Efficiency & Reduce Costs

Scaling up manufacturing presents both challenges and opportunities for engineers who must...

How to Scale Up Production with Chemical Milling & Etching

Chemical milling and etching are powerful techniques widely used in industries requiring precise,...

High quality products are made with high quality equipment. Stake your reputation on Chemcut.

Already a customer?

Chemcut’s commitment to you goes beyond the sale. We keep your equipment running with the industry’s best post-sales support, which includes our in-house R&D lab and global field service assistance.

We also maintain the industry’s largest and most diverse inventory of high-quality replacement parts to ensure prompt delivery regardless of the type or age of your Chemcut or MEI Division equipment.