Wet Processing Equipment Company

Chemcut’s process engineers have over 100 years of combined experience in wet processing.

Whether you are manufacturing printed circuit boards, sheet metal parts, wafers, or solar panels, Chemcut will find a way to make your wet processes successful. We are willing to customize our wet processing equipment to your every need.

Company

Chemcut has received the Pennsylvania’s Governors Environmental Excellence award twice since 1996. We have an outstanding safety record, the result of adhering to a stringent housekeeping and safety requirement program based on the Japanese “5-S” housekeeping system.

Chemcut is the world’s leading developer and supplier of wet processing equipment for photo chemical milling of thin metal parts, chemical engraving of signs and nameplates, etching printed circuit boards and metal finishing. We design and manufacture all of our equipment and machines in our 110,000-square-foot manufacturing facility in State College, Pennsylvania.

The concepts of Continuous Improvement, Deming and Imai (Kaizen) drive our value engineering efforts. This has lead to a 55% reduction in labor content of our product since 1992. Our employees are trained in fishbone and flow diagramming, charting, SPC, DOE, Force Field Analysis, team participation, etc.

We also manufacture wastewater treatment solutions for industrial applications utilizing ion exchange and sequential batch technology. Our wastewater treatment systems are efficiently designed to reduce operating cost and minimize maintenance cost. They also reduce disposal cost of hazardous materials through recycling of strip liquors back into the process. Made of corrosion resistant materials, Chemcut wastewater treatment systems can be designed for manual or automatic control for end of line or point of source applications.

Because of our expert design, manufacturing efficiency, and quality control, we are able to effectively compete on price and quality against any company or economy in the world.

Our Mission

INNOVATION

PRECISION

RELIABILITY

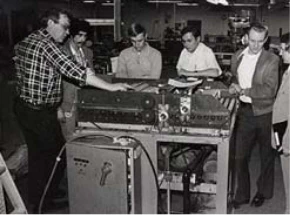

The foundational qualities that enabled Chemcut to develop the first conveyorized spray etcher in 1957 still drive our company today.

Our mission is to deliver high-quality, reliable manufacturing solutions that are designed to meet each customer’s unique needs. We begin with a conversation; a conversation that is driven by a desire – a need – to fully understand the customer’s objectives. Only after we have that understanding can we move forward and fulfill our mission through innovative design, expert manufacturing, thorough “real-life” testing, and industry-renowned customer service.

Chemcut’s leadership and vision transformed the wet process manufacturing industry, and we continue to set new standards with each system we design, test, and build.

Chemcut – We listen. We solve.

History

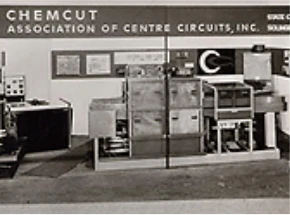

Originally named Centre Circuits, Chemcut was founded in 1956 as a manufacturer of precision equipment for printed circuit board production. One year later, the company sold its first Chemcut™spray etching machine. Chemcut etchers were at the forefront of technology innovation, as our mass-produced printed circuits quickly replaced handmade circuit boards.

Today, we continue to be the world’s leading developer and supplier of wet processing equipment for photo chemical milling of thin metal parts, chemical engraving of signs and nameplates, etching printed circuit boards, metal finishing, specialized glass processing for flat panel and touch-screen displays, photovoltaic (solar) panel manufacturing, and non-traditional processing of semiconductor products.

You can count on our experienced engineers and chemists to listen closely and to understand fully your specific needs and objectives. We will then design and trial your process in our in-house lab prior to final production, assuring the delivery of a proven manufacturing solution backed by decades of experience and world-renowned reliability and customer service.

Chemcut Customers

Since 1957 we have been a leader in the wet processing equipment industry.

Starting with printed circuit boards (PCB) we have expanded our offering into photo chemical milling of thin metal parts, chemical engraving of signs and nameplates, etching printed circuit boards, metal finishing, specialized glass processing for flat panel and touch-screen displays, photovoltaic (solar) panel manufacturing, and non-traditional processing of semiconductor products.

Today we continue improving our machines so our world-class customers can continue making groundbreaking parts.

High quality products are made with high quality equipment. Stake your reputation on Chemcut.

Already a customer?

Chemcut’s commitment to you goes beyond the sale. We keep your equipment running with the industry’s best post-sales support, which includes our in-house R&D lab and global field service assistance.

We also maintain the industry’s largest and most diverse inventory of high-quality replacement parts to ensure prompt delivery regardless of the type or age of your Chemcut or MEI Division equipment.