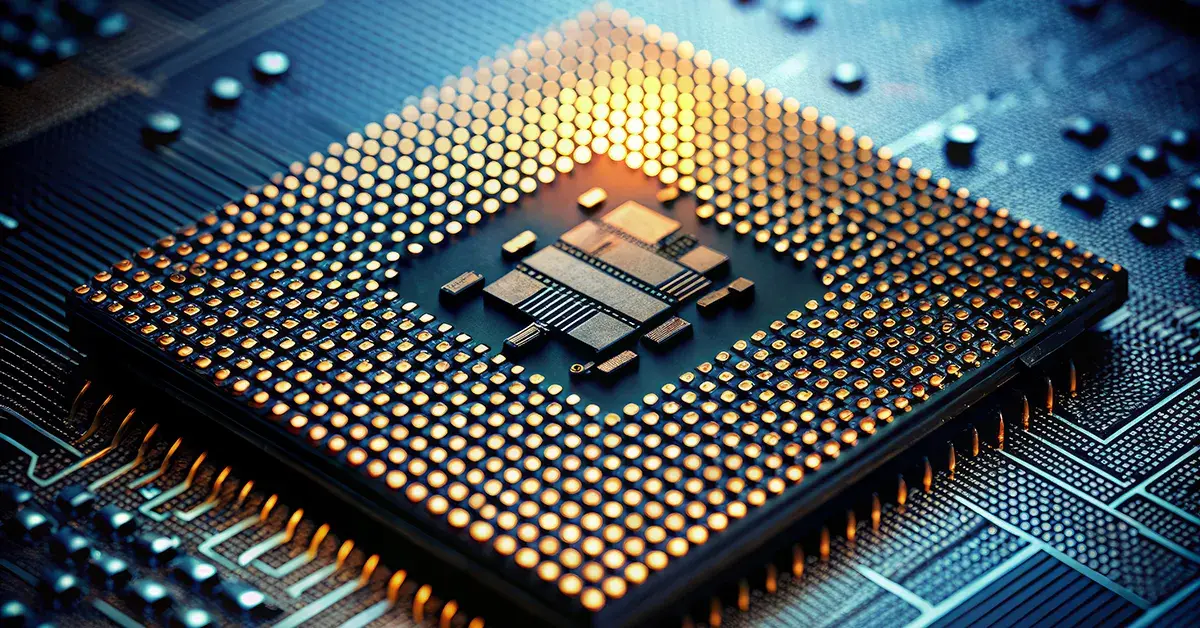

Printed Circuit Board (PCB) Fabrication Using Chemical Etching

Products & Processes Run on Chemcut PCB Etching Machines

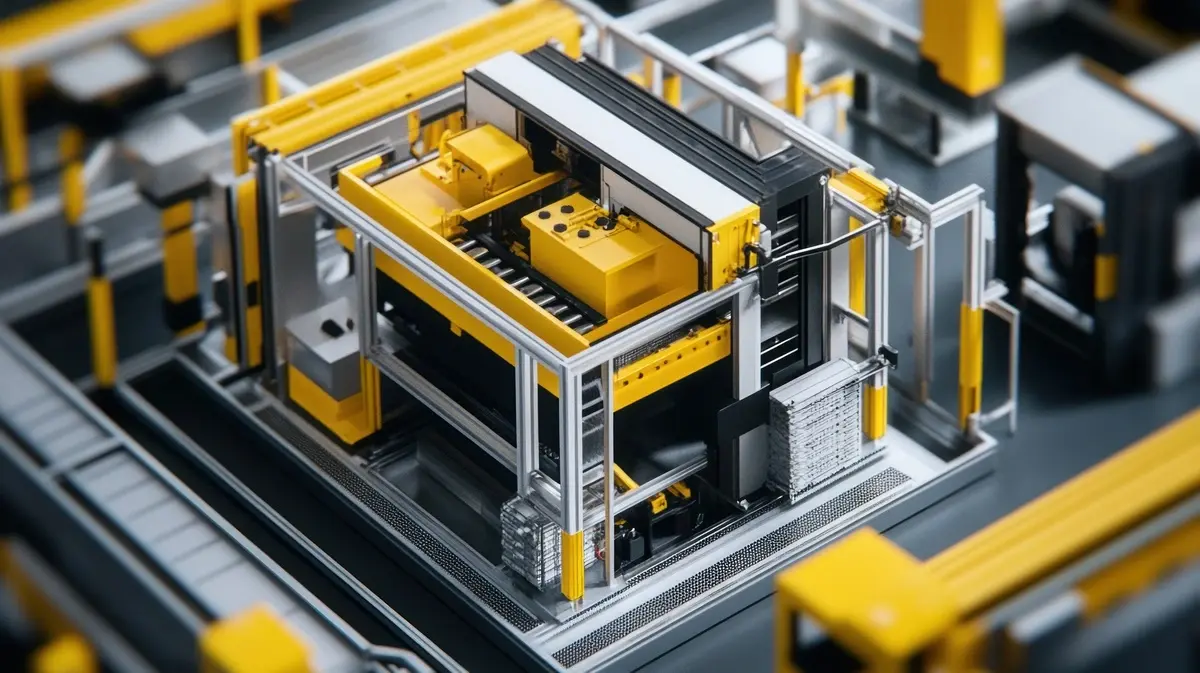

XLi with External Automatic Pressure Adjust

Control the spray pressure of each spray tube using the PLC instead of the throttling screw.

Available Conveyor Widths

- 20″

- 30″

- 40″

- 50″

- 60″

Common Processes

- Custom Size (1 to as many chambers as you want)

- DES (Develop – Etch – Strip)

- Etcher (Stand Alone)

- SES (Strip – Etch – Strip)

Common Chemicals

- Alkaline Etchant

- Cupric Chloride Etchant

- Ferric chloride Etchant

- Hydrofluoric Acid (HF)

- Micro etch

Common Materials Etched

- Aluminum

- Copper

- Glass

- Steel

- Titanium

- And more

2300 Series Chemical Cleaning System

Available Conveyor Widths

- 15″

- 20″

- 30″

Common Processes

- Cleaner (Stand Alone)

- Alkaline Clean to Acid Clean

- Custom Size (1 to as many chambers as you want)

Common Chemicals

- Acid Cleaner

- Alkaline Cleaner

CC8000 Chemical Cleaning System

Available Conveyor Widths

- 20″

- 30″

- 40″

- 50″

- 60″

Common Processes

- Cleaner (Stand Alone)

- Alkaline Clean to Acid Clean

- Custom Size (1 to as many chambers as you want)

Common Chemicals

- Acid Cleaner

- Alkaline Cleaner

XLi Chemical Cleaning System

Available Conveyor Widths

- 20″

- 30″

- 40″

- 50″

- 60″

Common Processes

- Cleaner (Stand Alone)

- Alkaline Clean to Acid Clean

- Custom Size (1 to as many chambers as you want)

Common Chemicals

- Acid Cleaner

- Alkaline Cleaner

2300 Series Dryer

Available Conveyor Widths

- 15″

- 20″

- 30″

- 40″

Features

- Stand-alone drying system

- Portable unit (move anywhere in the shop) or fix it in place

604 Deburrer

Features

- 2 oscillating brushes

- Built-in Rinse and Dryer

Common uses

- Post PCB drilling

- Post punching operations

219 Scrubber

Features

- Single-sided abrasive brush

- Tough reinforced conveyor belt supports small parts

Etch Adjust Module (EAM)

Add EAM to

- CC8000 Etching Systems

- XLi Etching Systems

Advantages

- Plated boards: Correct side to side etch difference when one side is plated more

- Fine-tune very small features

2800 Drawer Etcher

Features

- An adjustable drawer type rack

- Loads parts horizontally up to size 21″ x 21″

- Oscillating spray tubes

- Oscillating rack to maximize etchant movement

903-907 Regeneration System

Features

- Cupric chloride regeneration

- Ferric chloride regeneration

- Capable of utilizing: chlorine gas (903, 907C), hydrogen peroxide (907H), sodium chlorate (907H)

990D Electroless Plating System

Product Lines for Electrolytic and Electroless Plating: CC8000, Dip Tanks, XLi, 2300 Series

Common Processes

- Desmear

- Electroless Copper Plating

- Electroless Nickel Plating

- Electrolytic Copper Plating

- Electrolytic Gold Plating

- Electrolytic Silver Plating

- Electrolytic Tin Plating

- Immersion Gold Plating

- Immersion Silver Plating

- Immersion Tin Plating

- Ni/Au Plating

- PTH (Plated through-hole) Any discussion on this topic should include your chemistry supplier as well. It is critical that the bath for PTH is monitored closely.

- Inner layer bonding operations: brown oxide (Bondfilm, Multibond, etc.), (white ‘oxide’ – immersion Tin)

Ion Exchange System

Features

- Closed-loop system

- Decrease your water usage by connecting an ion exchange to your rinse water

Popular Chemical Etching Lines for Photo Metal Etching

Fine Line PCB Etching

Thin Material Transport for PCB

- 2 mil material can be transported with ease

- 1 mil Kapton transportation is currently in development and very close to being production-ready

Related Resources

Optimize a Wet Processing for Design & Spacing

Effective space planning and design are critical to the success of wet processing facilities....

How to Scale Up Manufacturing | Strategies to Improve Efficiency & Reduce Costs

Scaling up manufacturing presents both challenges and opportunities for engineers who must...

How to Scale Up Production with Chemical Milling & Etching

Chemical milling and etching are powerful techniques widely used in industries requiring precise,...

Customize your own equipment by telling us your needs, and we will engineer a machine around your product.

Already a customer?

Lorem ipsum dolor sit amet, consectetur adipiscing elit, sed do eiusmod tempor incididunt ut labore et dolore magna aliqua. Consectetur adipiscing elit, sed do eiusmod tempor incididunt ut labore.