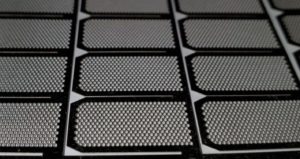

Photo Etching on Metal – Stainless Steel, Titanium, and More

What is Photo Etching?

Photo etching is the process of removing metal by chemical etching and is ideally suited for the production of flat, relatively thin parts of unlimited configurations.

Photo etching is also known as metal etching, chemical milling, acid etching, and stainless steel etching. If you wish to learn more about the benefits of chemical etching and why you should consider it, please see our page on etching.

Popular Chemical Etching Lines for Photo Metal Etching

Cupric Chloride Etcher

Copper Etcher

PCB Etcher

Ferric Chloride Etcher

Copper Etcher

Stainless Steel Etcher

PCB Etcher

Specialty Metal Etcher

Hydrofluoric Etcher (HF etcher)

Titanium Etching

Specialty Metal Etcher

Develop – Etch – Strip

Develop – Etch

Etch – Strip

Standalone Etcher

Mechanical Scrubber

Mechanical Deburr

Popular Options for the Photo Etch Process includes:

Specific gravity and drip pans are highly recommended options to go along with photo etch processing equipment. More options that can better your process can be found here.