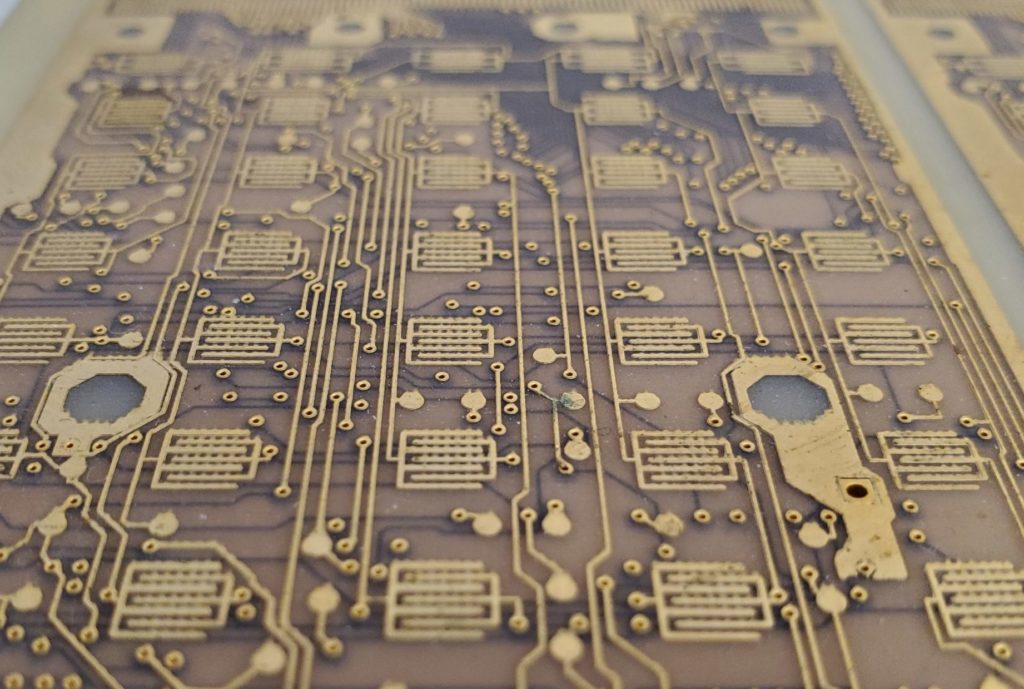

Chemical Etching for PCBs, Chemical Machining, and Much More

Product Lines for Metal

Common Acids Used for Engraving Metal and Glass

Alkaline (printed circuit board etcher)

Etch Machine for PCB

Cupric Chloride (printed circuit board fabrication)

Etch Machine for PCB

Ferric Chloride (Photo etching process and printed circuit board etcher)

Stainless Steel etching

PCB manufacturing

Specialty metal etchant (list of specialty metals)

Hydrofluoric Acid (chemical milling and glass etching)

Titanium etcher

Molybdenum etcher

More specialty metal etchers

Other uses for Chemcut etchers

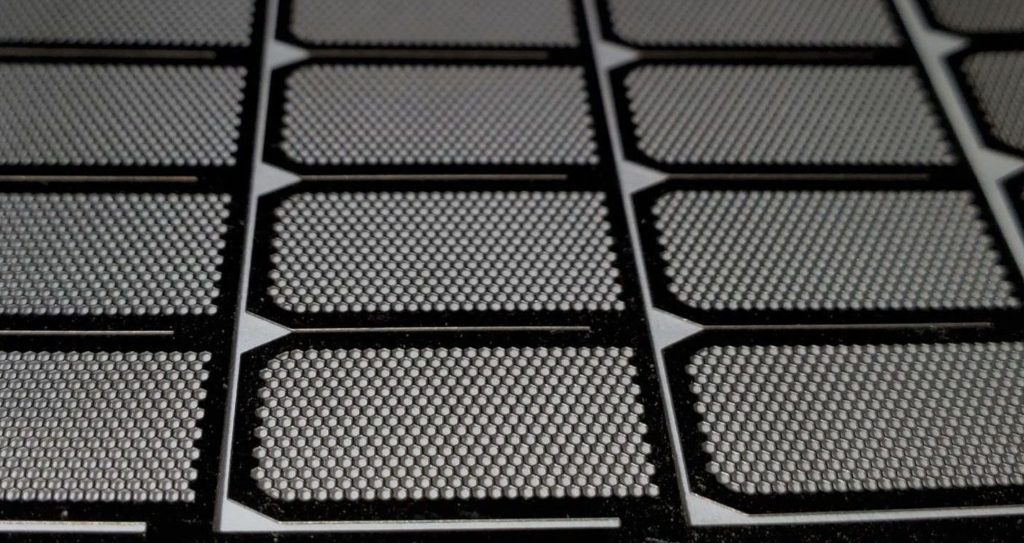

Custom semiconductor processing

Etcher for proprietary processes

Benefits of Chemical Etching Process

Accurate and Complex

Metal etching has the capability to make extremely complex designs and accurate metal components. Since all the features are being machined at the same time the complexity can be endless.

Bur Free and Stress Free

Since the etching process is chemical machining instead of mechanical machining the components will be bur free, stress-free, and will maintain all its original metal properties.

Fast Prototyping and Quick Design Changes

Metal etching has a digital tooling process that allows etcher owners to make fast changes to component designs.

Endless Metal Options

There is a list of metals that Chemcut has built chemical etchers for on our Chemical Milling Page.

Common Line Parameters

Speed range: 14 – 140 inches / minute

Max temperature: 130 °F

Processes will vary depending on metal, etchant, and desired properties of product.

Why should a company add chemical etching to its capabilities?

No stress hardening

Burr free – stamping produces parts with sharp edges, requiring removal for safe handling

Unlimited complexity. Typically, chem milling companies charge for the first hole

Quick turn around on redesigns – giving the ability to produce multiple prototype designs with minimal down-time

Quick and cheap prototyping because the artwork is inexpensive

No expensive hard tooling like stamping

Etched parts are NOT compromised by contamination. Many parts are used in the medical field

Nearly any metal can be etched in a Chemcut machine

Acid Etching metal on a Chemcut machine can have a tolerance of 10% of the material thickness; even better with artwork compensation prior to resist exposure

Tolerance of 1 mil and lower is achieved by many of our customers.