Printed Circuit Board PCB Fabrication Using Chemical Etching

Products / Process Run on Our PCB Etching Machines

2 mil core inter-layers

Flexible reel-to-reel Kapton

250 mil multi-layers

Rigid FR4

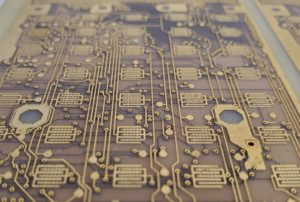

Fine Line PCB Etching

2 mil line and space at production volumes

Thin Material Transport for PCB

2 mil material can be transported no problem

1 mil Kapton transportation is currently in development and very close to production-ready

Etch Tests / Proving Capabilities

Samples can be tested in Chemcut’s R&D lab to prove our etcher can process your parts before purchasing a machine. Other wet processing tests are available upon request.

Chemcut’s R&D lab is open to be rented for research. Chemcut can perform any wet processing step needed.

Popular Wet Processing Equipment for PCB

Develop – Etch – Strip Line

Strip – Etch – Strip Line (outer layers)

Cupric Chloride Etch Line

Ferric Chloride Etch Line

Mechanical Deburr

Mechanical Scrubber

Chemcut PCB Etching Machines for Fabrication of PCB

Chemcut has been a leader in the PCB etching process since 1957.

We have used the concept of continuous improvement to ensure our etchers and other wet processing machines are of the top quality throughout our history.

With that said we are on the continuous improvement path to outdo ourselves once again!

To keep up with the PCB board industry we are developing a thin transportation system that will pass 1 mil Kapton through our etcher and rinse stations without fail. No leader required.

Along with thin material transport, Chemcut has improved our etch uniformity continuously. If you were to buy a Chemcut etcher you would be able to etch 2 mil line and space with no issue.

If you desire to etch a line and space smaller than 2 mils you will need to use thinner copper. The thinner the copper you etch the smaller the etched line and space can be.

Need better uniformity still?

Chemcut has you covered with its patented Intermittent Spray and Etch Adjust Module.

The Intermittent Spray eliminates the puddling effect by giving extra etch to the middle of the panel. This will flatten out the etch uniformity front to back.

Etch Adjust Module is for those small hot spots you sometimes have side to side. This is a popular option for plated boards for the thickness can vary from side to side.

On top of our thin material transport and etch uniformity and accuracy Chemcut pulls away from the pack with our extra engineering options.

Would you prefer to control the spray pressure of every spray tube or zone (depends on setup) instead of the options above?

Then check out our NEW XLi High-Resolution etcher! This NEW module allows you to control the spray pressure of every spray tube/zone using your PLC.

We have designed our new XLi High-Resolution etcher to have 5 zones top and bottom where you can control the pressure of each spray tube/zone. This etcher will allow you to even your etch side to side for PCB fabrication and will allow you to etch one side more than the other without getting in the etch chamber to make adjustments.

Learn more about our NEW XLi High-Resolution Etcher

One of the most popular money saving options is our Regeneration system. Chemcut’s regeneration system on average triples the life of ferric chloride etchers.

As for cupric chloride, Chemcut’s regeneration system makes the chemistry last forever! The regeneration system will automatically add hydrochloric acid and sodium chlorate as you etch more copper.

Chemcut also offers a chlorine gas regeneration system.

Other popular options for the PCB etching process includes:

Specific gravity, ORP, and pH controls are all options that are widely popular in PCB etching. There are plenty more options PCB processing that can be found here.