Developer for Photoresist to Achieve High Resolution

Product Lines for Photoresist Developers

Common Photoresist Developers

Photosensitive Dry film Developer

Photosensitive Liquid Resist Developer

Photosensitive Solder Mask Resist Developer (Dry and Liquid)

Common Uses for Developers

PCB Photoresist Developer

Photo Etching Photoresist Developer

Glass Resist Developer

Semiconductor Developer (SEMI)

Wafers Developer

Photoresist Developers Parameters

Speed range: 14 – 140 inches / minute

Max temperature: 90 °F

pH range 10.5 – 11

Important Pre-Developing Steps

Alkaline and Acid Clean (Chemcut Processes)

Cleaning the metal surface is extremely important when it comes to developing. A clean surface means no dirt to interfere with the exposure step and it helps with lamination adhesion.

Alkaline Clean is the first cleaning step and is used to remove all oils and organics from the surface.

Acid Clean is the second cleaning step and is used to remove any contaminants that remain on the surface. This chemistry will micro etch the surface which increases lamination adhesion.

Increase lamination adhesion for chemical milling companies, they should make their rinses after the acid clean slightly acidic. A slightly acidic rinse will create an acid surface that reacts with the lamination to help with adhesion.

Increase lamination adhesion for the PCB industry companies will micro etch the surface prior to lamination.

Lamination (Non-Chemcut Process)

Hot Roll Lamination, to increase resist adhesion and to avoid photo resist wrinkling you should pre-heat the board before applying the dry film photoresist. Especially if the metal is thick.

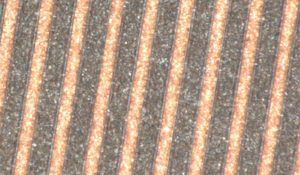

Liquid Resist is recommended to attain high resolution for developing and etching.

Thinner Photoresist typically gives tighter tolerances because the channel the chemistry needs to get in is shorter. A shorter channel allows the chemistry to flow in and out better.

Hold for 30 minutes after lamination to allow the resist to lock into the metal.

Exposure (Non-Chemcut Process)

As everything keeps getting smaller this has become one of the most important steps.

A speck of dirt is enough to cause an open circuit on fine lines. The slightest misalignment on artwork top to bottom has the potential to shift dimensions outside the tolerances.

This isn’t a Chemcut process, but we have been around long enough to gain knowledge on photoresist exposure. Below is a small list of topics we believe are important for the best exposure:

Clean

Yellow room is a must have

Collimated light for fine features

Features that help create near perfect alignment

Hold for 30 minutes before developing for better resolution

Developing Step

Developing is normally looked at as less critical than etching. This is true, BUT it doesn’t mean you can overlook the developing step.

Photoresist can be underdeveloped or overdeveloped.

Underdeveloped means all the unpolymerized resist was not completely removed. So, you did not fully expose the metal that you want to etch away.

This results in smaller holes or no breakthrough for chemical milling and shorts for circuits.

Overdeveloped means, the developing solution started to undercut the resist. This means the resist may lift while etching which means you are losing resolution and worse etch away metal you want to keep.

For chemical machining, you may end up outside your tolerances and for circuits, you may end up with open circuits.

Important Post Photoresist Developing Steps

Optional Step to Increase Lamination Adhesion

Bake is the most commonly used step to increase resist adhesion. The major downfall of this step is the time it takes to complete.

UV Bump is a much quicker step. However, it does not increase adhesion nearly as much as baking does.

Etch

Strip