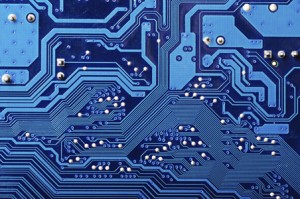

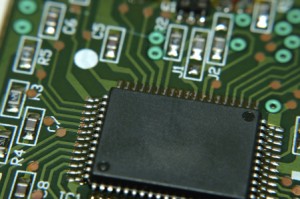

Chemcut custom-designs and manufactures horizontal wet processing equipment for organizations of all sizes – from small-scale laboratories to large mass production operations – and across a wide range of industries. We frequently serve the industries highlighted below, in addition to a wide range of others, including Automotive, Solar, Video Display, Medical Device, Printing, and more.

Whether you’re building a new business or expanding an existing one, no matter what industry you serve, depend on Chemcut to design and deliver the custom wet processing machines you need and can rely on for the long-term.