At Chemcut, one of the matters we prioritize is providing our customers with equipment that can provide you with an efficient etching method. Overall, 2 basic metrics contribute to etcher efficiency: production rate and etch quality. Today, we are to talk about a specific factor that affects etch quality – etch uniformity across panels.

About Etch Uniformity

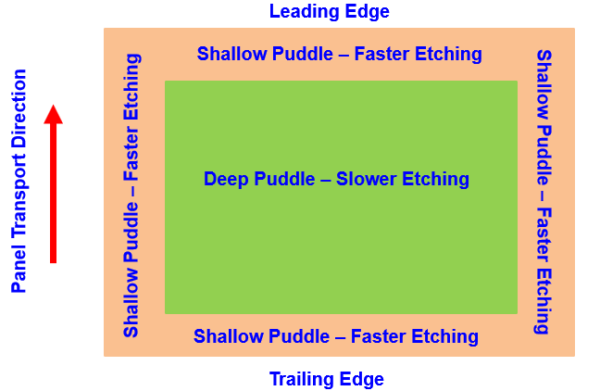

In chemical etching, larger panels tend to have variation across them. Typically, on the top side of a panel, the middle of the panel etches slower than the edges because of the rate fresh etchant diffuses from the middle out. This is what is referred to as the “puddle effect”. It is called this because it is observed on the top side of a horizontal conveyorized etcher.

Getting around the puddle effect comes with challenges, however, there is technology available to combat it. For instance, in a previous blog post, we discussed how you can utilize intermittent spray. To recall, intermittent spray is a module that we build that creates a timed spray that focuses on the middle of the panel. This is an effective tool for correcting leading-to-trailing edge variation (variation in the direction of the conveyor movement). We have found that this works best when paired with an additional piece of technology that is focused on side-to-side etch uniformity. That piece of technology is our “Etch Adjust Module” (EAM).

What is the “Etch Adjust Module”?

The EAM is a piece of equipment that you can add to your modular-built etcher. It provides you with a small virtual etch chamber that contains multiple spray tubes that each can be set to different spray pressures. This allows you to focus more spray pressure on the edge or in the middle of the panel. Originally the EAM was made for creating adjustments on copper-plated panels that have tapering from the plating process. Although its original purpose was correcting variation from plating, it has also proven to be useful in controlling side-to-side etch uniformity. By giving you full control of how much you etch in a particular location, it gives you the freedom to add independent spray zone control to any etching equipment you have.

If you are interested in finding out more about our approaches to etch uniformity, please feel free to contact us with any questions.