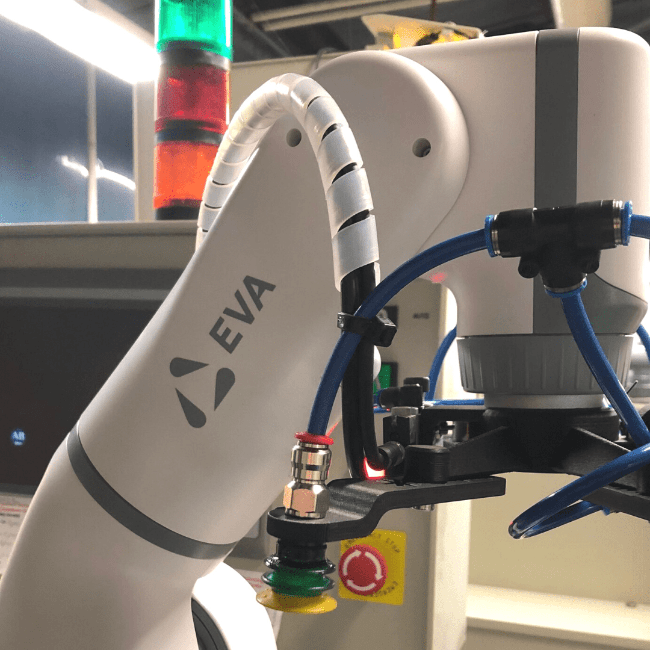

Are you someone who is looking for more automation for your etch shop? If so, then we would like to introduce “EVA” — the highly anticipated solution for material handling. Just last month, EVA made its premiere at the IPC APEX EXPO. There, EVA caught the eyes of many people who have been searching for this technology with wet processing equipment. If you did not get the chance to visit us and see EVA in action, then allow us to provide you with a proper introduction to EVA and some of its features.

Adaptable Functions

EVA can handle material in almost any way you desire. Whether you want it to pick up thick or thin sheets, wet or dry material, or large or small panels — it can do that. Also, with EVA’s 6-axis operation, it can maneuver and function in almost any way you need.

What is also great about EVA’s design is that it is compatible with all our equipment. If you are looking to add an EVA unit to your current etch line, that is something you can do.

Intuitive Programming

Programming EVA to perform a task is simple and intuitive. The platform EVA runs on provides you the option to manually or digitally (through a device) adjust EVA to set points. Through this, you can set a series of waypoints to create and save programs for future use. If you have different motions you would like it to go through, you can create multiple programs and initiate them whenever you need.

Smart Capabilities

Another great feature about EVA is that it can be operated from your tablet or smartphone. With this ability, you can load a panel into your etching machines, change to a new program, or stop it without having to be right next to the machine.

Compact Design

EVA’s design is compact and can work with whatever space limitations you have. Even if you are low on working space, you do not have to concern yourself with the new footprint; EVA’s addition to our equipment hardly adds any length or width.

EVA will make a unique addition to your overall daily operational throughput and efficiency. Once set up, EVA will operate autonomously and free up skilled employees to focus on more important technical issues and overall quality control. Contact us for a free demonstration of EVA today and learn how this little robotic arm can benefit your daily operations.