If you are working in the chemical etching industry, safety should be one of your top priorities. A chemical etching shop in irresponsible hands can become a dangerous place because of the many physical and chemical hazards. In this article, we will share some useful safety tips we have learned over many years in the chemical etching industry. Utilizing these tips on top of normal safety procedures and policies will ensure your chemical etching shop becomes a safe place to work.

1. Mind the edges

After etching, any edges exposed to the etching process become sharper. Because of this, it is highly recommended to handle etched panels with gloves that will be resistant to any punctures or slashes that the edges can inflict. This is more of a concern in the field of chemical etching because parts are etched through. In the printed circuit board industry, sharp edges are produced less because there is no point where the top and bottom etching meet to form a refined knife-like edge.

2. Double-check valves

Right before you perform any task with or on your wet processing equipment, it is a good idea to double-check the valves. This will ensure there will not be an accidental release or exposure to the chemistry. It will also allow you to ensure that the necessary process controls are active.

3. Don’t leave a filling machine unattended

When you are loading an etcher with water or etchant, it may be tempting to step away and do something while you are waiting. The problem here is that it is inevitable that someone will forget and overfill the machine. When a machine overfills, the contents will begin to overflow from any openings — this becomes a hazard in the workplace because of the possibility of slipping on the wet floor and being exposed to the etcher chemistry.

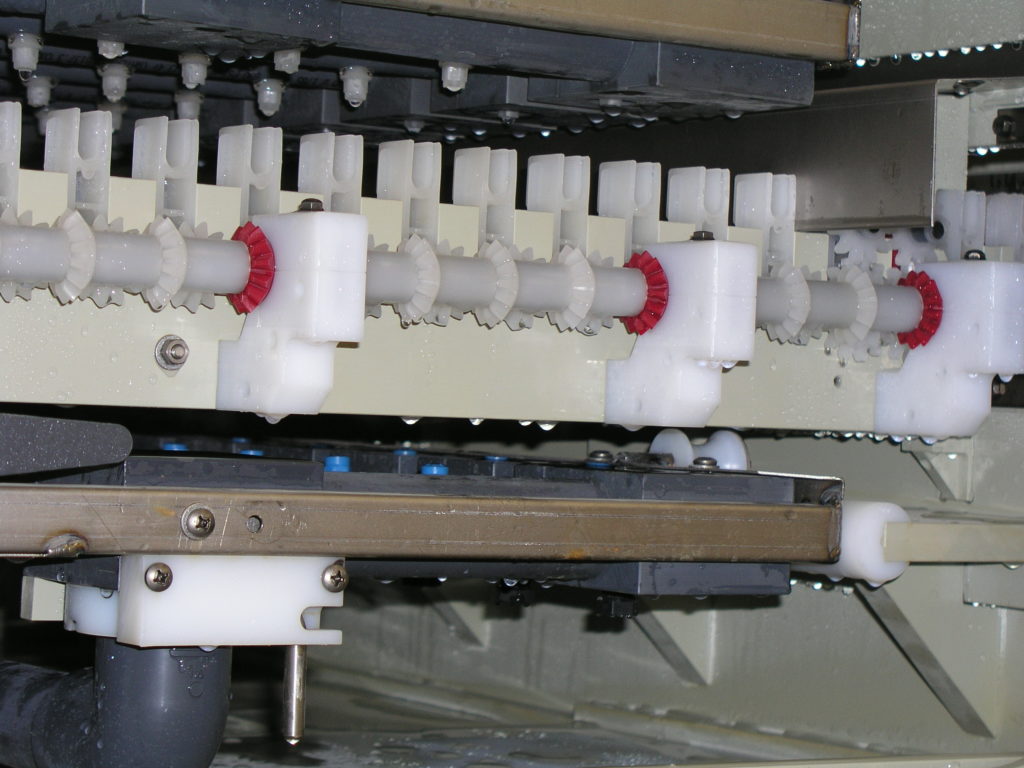

4. Reduce time working inside the etcher

Working inside the etcher can be an uncomfortable part of performing maintenance. Whether you are reaching into the etcher to troubleshoot or perform preventive maintenance, it is always best to allow the etcher to cool down to room temperature before performing tasks. If immediate access is needed, it is best then to minimize the amount of time inside the etcher and to reduce skin contact with the wetted interior. Most etchants can irritate the skin and produce toxic fumes when hot.

5. Maintain a preventive maintenance program

To prevent unexpected events of exposure, it is important to perform inspections often. Always check seals, plumbing, and containment to ensure there is no compromise. Preventive maintenance keeps your equipment in top condition and prevents any sudden, accidental releases of the contents inside any wet processing equipment.

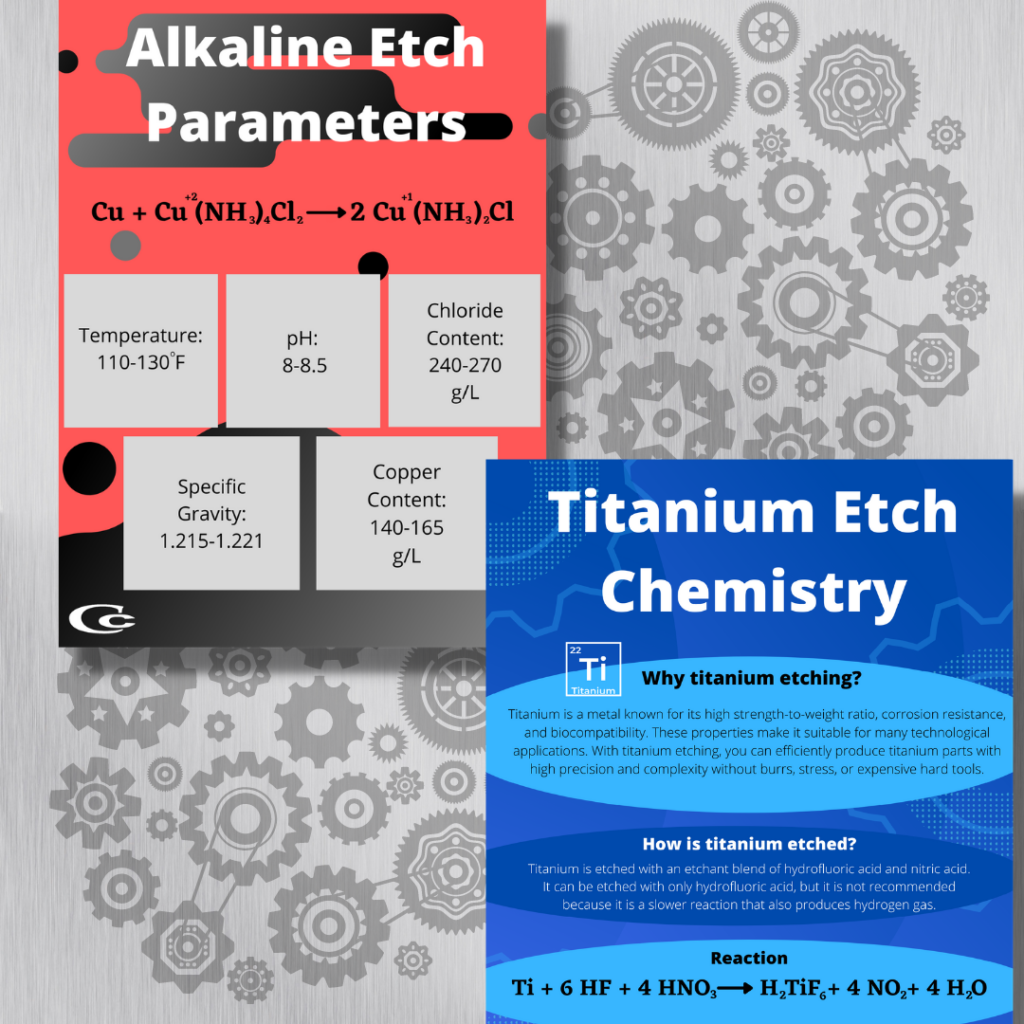

6. Understand the active chemistry

In chemical etching, it is highly important to understand your etching chemistry. Understanding what materials or chemicals may react can go a long way in terms of safety. It is easy to underestimate what reactions can occur with your chemistry. If an incompatible component is added, the outcomes can range from a highly exothermic reaction to a release of toxic gas.

Maintaining a safe environment in the chemical etching industry is highly important. If you follow these tips you’ll be a few steps closer to having a safer chemical etching shop.

Are you looking to make your chemical etching shop safer? At Chemcut, we offer an extensive preventive maintenance agreement that is customer-specific. This program could be annual, semi-annual, monthly, or whichever works best for you. Should you be interested in this type of service, please contact our service department.